At Chemours, we are firm believers in the power of advanced chemistry to deliver cutting-edge solutions to industries critical to the nation’s health, prosperity and security.

Chemours creates materials and products — including fluoropolymers — that are key components in everything from cars and smartphones to medical devices and clean energy technologies. Fluoropolymers contain carbon-fluorine bonds, the strongest bonds in organic chemistry, and possess unique combinations of properties that make them durable, efficient, reliable, versatile and fundamental to the products they enable.

We put science first, and we’re driven by our commitment to responsible manufacturing. To us, that means setting ambitious corporate responsibility goals and applying investment, creativity and energy to achieve them.

Our scientists, engineers and site personnel are delivering results. We have developed advanced sampling, measurement and analytics capabilities and implemented industry-leading water recycling, emissions control technologies and much more.

Developing advanced analytical capabilities

Reliable, validated and reproducible analytical methods are essential to sound, fact-based decision-making.

The ability to accurately measure the emissions of fluorinated organic compounds is a first and necessary step on the path to meaningful emission reduction. We are proud of our leadership in this space.

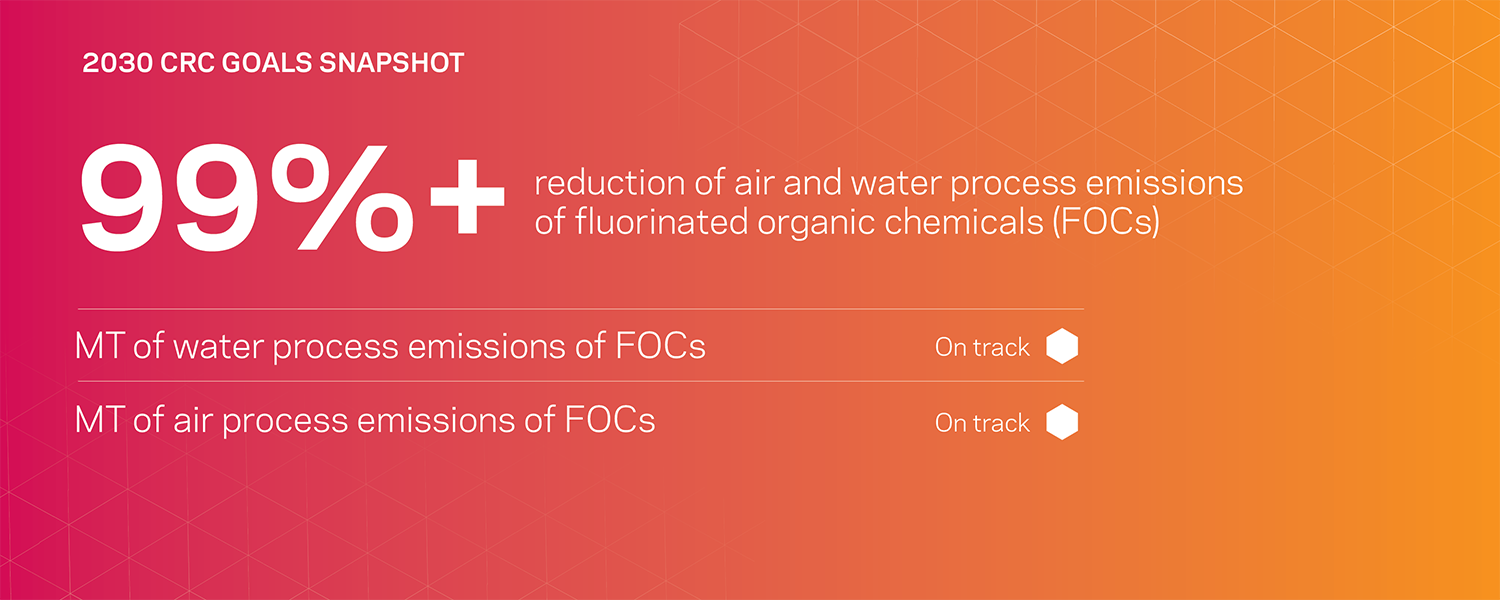

Chemours is the first chemical manufacturing company to make a voluntary public commitment to eliminate at least 99% of fluorinated organic compound emissions to air and water from our manufacturing processes by 2030. We know of no other company that has made this public commitment.

We measure our progress toward this goal with a state-of-the-art method of air stack testing we’ve pioneered at our Fayetteville Works site — and freely shared with academic institutions, industry peers and regulators. Our team of scientists significantly modified an existing stack sampling method for HFPO-DA, a compound we use in the production of fluoropolymers, and validated it in only eight weeks. The method proved so robust that it has since been used for several dozen other compounds, and we use it across several manufacturing sites to better quantify and understand our environmental impact. The EPA’s Method 45 (OTM-45) is modeled after this sampling train designed and optimized by Chemours.

Chemours also synthesized and provided authentic standards for our external testing labs, regulators and researchers so they can analyze and quantify the presence of compounds in samples collected through advanced air and wastewater sampling techniques.

Implementing industry-leading water recycling technologies

At our Fayetteville Works facility, we have piloted a state-of-the-art reverse osmosis system that allows us to capture wastewater from the site, filter it and ultimately recycle demineralized quality water for further use on the Fayetteville Works site. The system utilizes spiral-wound membrane elements designed for high pressure and high rejection of dissolved solids in water. The effective pore size is small enough to reject a very high percentage of per- and polyfluoroalkyl substances (PFAS).

Our efficiency testing of the system shows that PFAS compounds are removed at an efficiency of greater than 99%.

We are not aware of any other companies that have implemented and optimized this technology to the extent Chemours has.

Reducing greenhouse gas emissions

At our Louisville Works site, we have launched projects and implemented process improvements that will both reduce fluorinated organic compound emissions and significantly reduce greenhouse gas emissions and support our company-wide goal to reduce scope 1 and scope 2 emissions by 60% by 2030, positioning us to reach net-zero greenhouse gas emissions from our operations by 2050 and to continue our contribution to the Paris Climate Agreement goals.

These efforts have been complex; the size and scale of the Louisville system and components required custom design, with significant lead time for manufacturing and shipping. We currently capture and destroy the majority of HFC-23 process emissions at the Louisville site. By the end of this year, we expect to have refined the capability to capture and destroy at least 99% of HFC-23 process emissions at Louisville.

We are not stopping there. We have a second project underway to reduce HCFC-22 emissions at the site. Our process improvement project will put technologies in place to capture and recycle the compound within the manufacturing process, preventing its emission and reducing the need to manufacture additional volumes. We have selected the technology platform and are working through engineering and analysis to ensure optimal process design. We expect this project to be completed by the end of 2024.

Looking ahead

When we established our corporate responsibility goals, we knew it would take sustained effort and innovation to achieve them.

Our work to advance our analytical capabilities, enhance our water recycling technology and substantially reduce greenhouse gas emissions are three of many examples of our complex, long-term work to deliver results.

Across Chemours, other projects are in progress, and plans are being developed for future improvements.

We can create a better world through the power of advanced chemistry. Our products are already at work, enabling transformative innovations like the onshoring of semiconductor manufacturing and the decarbonization of transport. And we’re committed to ensuring, through close partnership with in-house and third-party scientific experts, that progress takes place in the best way possible for people and the planet.